BMW’s Energy Program: Clues to Breaking the Generation Monopoly?

BMW’s massive Spartanburg plant has something special under the hood. Powering its plant includes a system that reduces reliance on an already overtaxed energy grid. So why have you never heard about it? And more importantly, is it just a virtue-signaling venture, or is it a small glimpse into the future of independently produced power in South Carolina?

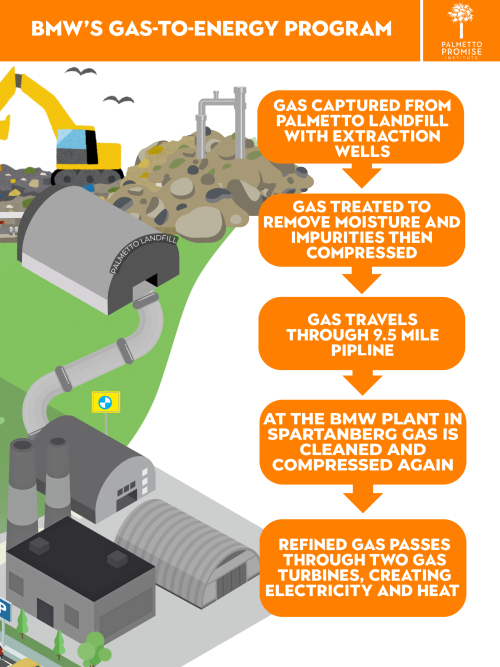

How it works: turning trash into power

BMW’s in-house energy production starts at the Palmetto Landfill in Wellford, South Carolina. At the landfill, landfill gas (LFG), naturally released by decomposing waste, is captured by extraction wells. After being captured, the LFG, primarily composed of methane and carbon dioxide, is treated to remove moisture and impurities. The gas is then compressed at the landfill’s recovery and compression station. The gas then travels through a 9.5-mile pipeline to BMW’s Spartanburg plant. Upon arriving at the plant, the gas is cleaned and compressed again, preparing it for the plant’s energy center. In the energy center, the gas travels through gas turbines, producing electricity and heat.

How did BMW get into the energy production space?

BMW opened in South Carolina in 1994 and entered the biogas energy production space in 2002 through a partnership with Ameresco, a Massachusetts-based renewable energy firm. Their joint efforts led to the completion of the plant energy system and pipeline in 2003. The energy project represents a large expenditure, but for BMW, it has been worth it. BMW has spent $14.8 billion on developing the Spartanburg plant through seven major expansions since 1992. For an investment of that size, energy control means price stability in the face of price hikes and a positive environmental impact.

The energy system “resulted in a best-in-class project to harness the power of biogas solutions to usher in a cleaner era for the auto industry,” said Michael Bakos, Ameresco’s Executive Vice President.

Does the LFG program live up to the hype?

BMW generates more than 20% of its own energy if sources besides the landfill gas program are taken into account. Gridinfo.com estimates that in the past year, BMW’s plant produced 32% of its energy (90% of that being LFG and the rest being natural gas and a small amount of solar energy).

But, looking at a graph of BMW’s LFG energy generation on the U.S. Energy Information Administration (EIA) website and others, there is a trend of declining LFG energy output. At the same time, BMW has increased its reliance on natural gas. Nevertheless, even with declining output and questions about viability, the LFG program still seems to be the “win-win for Upstate South Carolina” that Dr. Robert Engelhorn, president and CEO of BMW Manufacturing, said it was.

What is the impact on SC?

BMW’s energy initiatives still deliver significant benefits. According to inflation-adjusted estimates based on 2009 data, the Spartanburg plant saves approximately $10.5 million annually in energy costs by generating its own energy. BMW savings may contribute to lower electricity prices regionally due to reduced demand on local utilities.

BMW’s broader economic impact in South Carolina is unprecedented. A 2022 study by the Darla Moore School of Business at the University of South Carolina found that BMW’s operations generate $26.7 billion in annual economic impact including both direct and indirect production. At the heart of this impact is Plant Spartanburg, which supports nearly 43,000 jobs. BMW works with more than 500 South Carolina-based suppliers, 90 percent of which are located in the Upstate. With such a robust local supply chain, BMW boasts an employment multiplier of 3.5, meaning that for every 10 jobs at Plant Spartanburg, another 25 are created elsewhere in the state. In both direct and indirect ways, BMW’s presence in South Carolina shows how companies can influence stretches well beyond the factory floor.

The Takeaway

While not without its limitations, BMW’s landfill biogas program represents a meaningful advancement in the field of energy because with it, a major industrial facility is utilizing a generation source of its own that is, so far as we know, independent of monopoly utilities.

In that sense, the BMW biogas program could serve as a model for the future of industrial and commercial electricity generation in South Carolina. As we have written recently, imagine the possibilities of allowing, say data centers, to provide their own load requirements fully independent of the grid. If that happens, BMW should be looked to as a pioneer.

The featured photo of BMW’s landfill gas pipeline was provided to us by BMW’s Spartanburg Plant.